Jacwud hardwood MDF is a composite wood panel made by extracting fibre from tropical hardwood and bonding them together using sophisticated Continuous Pressing Technology to form a homogenous board with density ranging from 750 to 850 kgs per cubic meter.

Jacwud Hardwood MDF is an eco-friendly product and an ideal substitute for other panel boards such as Marine Plywood, Commercial Plywood, Block board etc.. The astronomical growth of Jacwud could be attributed to :-

- Its ideal surface for Veneer or Melamine lamination.

- Perfectly suited for spray painting and lacquering

- Uniformed density for profiling or carving

- Screw holding properties matching to solid wood.

- Low thickness swelling properties.

- High resistance to Fungus.

- Natural Colour. No artificial colours like PINK or GREEN are used.

Jacwud MDF had endless use due to its versatility. It can be used for all interior furniture applications such as table tops, door panels, wall panels, architectural moldings, cupboards, kitchen cabinets, office furniture, photo frames, cot headboards and footboards, exhibition display panels etc.

A comparison of Jacwud Hardwood MDF with other MDF boards

| Jacwud Hardwood MDF | Other MDF |

|---|---|

| Tropical hardwood fibres | Softwood fibres |

| Higher Natural density | Density artificially created by adding dangerous chemicals |

| Natural colour | Artificial colour added which make the boards highly poisonous |

| 100% latex free | Latex packets present in most the cases |

| Fibres are washed before bonding | Not washed |

| Comparatively low emission | Very high emission |

| Uniform density | Density variation inside the board and board to board |

| A Stronger outer surface which saves paint consumption | Consumes more paint due to surface problems |

| Less Chance for bulging | High chance for bulging |

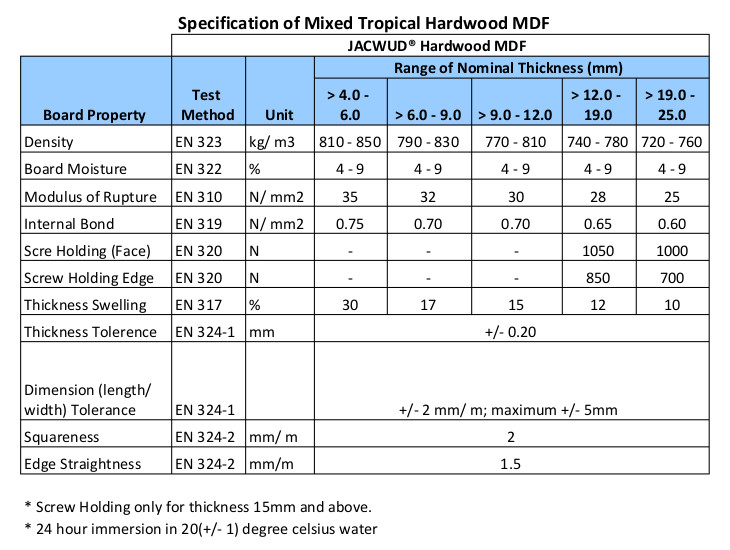

MDF SPECIFICATIONS

JACWUD MIXED TROPICAL HARDWOOD MDF

(100% Hardwood MDF)

The Sensible Alternative to solid wood.

Features:

- Borer Resistant

- Fungus Resistant

- Moisture Resistant

- Delamination free

- State of the art technology